Apr

10 reasons why OEMs worldwide choose Stöber servo systems

The range of manufacturers of servo drives is large... let's say very large. Not surprising given that automation with flexibly adjustable machines...

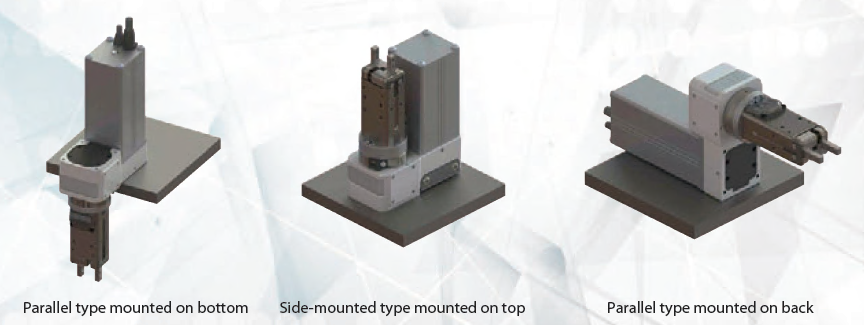

The IAI Rotary drive with gripper combines motorized rotation and gripping into a 1 efficient product.

The RCP6-RTCK comes with multiple advantages:

The IAI actuators are deliverd with drive and cabling. Specifications of the actuator like forces and number of mm each revolution of the motor are already fixed. Because of this a a quick and safe commissioning is guaranteed.

The software engineers at ATB Automation assist in programming and commissioning via the help desk or on site

Besides control with I/O the drive can also be controlled with EtherCAT and ProfiNet.

The SD6 drive also has the CANopen option available.

We supply slewing ring bearings, oscillating mountings, tensioner devices from stock and we also have spiral bevel gearboxes, servo gears and electromechanical actuators in our delivery program.

In addition we also select and offer the right components and systems for motion control solutions, such as servo gear motors, linear servo actuators and complete XYZ cartesian systems.

ATB Automation uses cookies to give you the best browsing experience possible on our site.

Continue to use the site as normal if you agree to this.

We use cookies on our website to create the most effective website possible for our users. Cookies are small text files that are sent to and stored on your computer, smartphone or other device for accessing the internet, whenever you visit a website. Cookies allow for us to measure and personalise. The cookies we use allow us to improve your experience when using our website and ensure the website performs as you expect it to. It also allows us to offer eg videos on our website and display social media share buttons. On this site, the cookies we use include 'analytics' cookies, to analyse how users use this site to help us make our website better for those who visit it regularly.

The settings below allow you to specify which cookies you accept. Please note that by not accepting all cookies, some parts of the site will not work properly.